TREATMENT OF WASTEWATER WATER CONTAMINATED WITH VARIOUS HARMFUL SUBSTANCES (INCLUDING OIL PRODUCTS) BY FLOTATION METHOD

A BRIEF DESCRIPTION OF THE PROCESS OF FLOTATION TREATMENT OF INDUSTRIAL WASTEWATER CONTAMINATED WITH VARIOUS HARMFUL SUBSTANCES (INCLUDING PETROLEUM PRODUCTS).

FORMED WATER FROM OIL WELLS IS COLLECTED IN SPECIAL TANKS AT THE APPROPRIATE TERMINALS. THE WATER IN THESE TANKS IS PUMPED EITHER DIRECTLY BY TANK TRUCKS OR TO TANK CARS AND TRANSPORTED BY RAIL TO THE COMPANY'S WATER TREATMENT PLANT.

WATER INTAKE (DISCHARGE) IS CARRIED OUT IN ACCORDANCE WITH THE REQUIREMENTS OF THE TECHNOLOGICAL PROCESS OF TREATMENT PLANTS.

The water treatment plant has all the necessary technical equipment (additional railway lines, trestle, appropriate water pumps, connecting hoses, valves, etc.) required for the reception and discharge of wastewater...

A tank with a capacity of 1000 m3 for receiving wastewater transported in the territory of the station, which fully complies with the technical (volume - constructive) requirements of the required technological treatment cycle of this volume of water, is provided. (Appendix № 4, p.4)

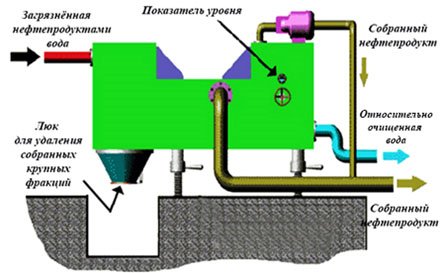

Water treatment technological cycle (Appendix № 4, p. 2 and page 3) it begins by discharging it into the sedimentation chamber of a mechanical treatment plant through a connecting pipe (Ø 159 mm).

Cleaning process ( See: Appendix № 4, p. 2 and page 3)

from the first stage: - sewage begins to pass through filters of different sizes (diameter of holes). Water stagnation is designed to separate substances with different densities than water densities. That is, in this case, heavy substances accumulate at the bottom of the water, and light substances accumulate on its surface.

Initial mechanical cleaning

Mechanical cleaning is used for sandblasting operations. Stabilizers, sprinklers and other devices are used here. In these devices, mainly coarse-grained compounds (additives) play a cleaning role. The process of mechanical cleaning is given in principle as follows:

With the help of mechanical treatment, it is possible to treat up to 65% of domestic wastewater and up to 95% of industrial wastewater. The main task of this method is to prepare wastewater for the next stages of treatment. This method has always proved its worth (both at the expense of inexpensive extractive materials).

Mechanical and chemical cleaning.

This method combines a flotation unit of chemical reagents and colloidal coagulants. Pressure floatator device (See: Appendix № 4, p. 6) designed for cleaning (separation) of petroleum products, suspended solids, oils and similar (similar) contaminants. The scheme of purified water circulation is implemented in this device (See: Video).

Initially, the wastewater is pumped to the flotator. Here, the reagent (See: Video).

Initially, the wastewater is pumped to the flotator. Here, the reagent (See: Appendix № 4, p. 7) the startup process is performed.

As can be seen from the kinematic diagram, containers containing chemicals for chemical treatment of water near the flotator-separator unit (Appendix № 4, p. 7)and special computer-controlled dosing pumps designed to deliver these substances to the system. Depending on the specific composition of each wastewater, in accordance with its treatment technology, these dispensers transfer the required reagents (chemicals) through the compressed air to the system-separator on the basis of special software.

Preparation of water-air mixture is carried out as follows:

The pump takes (30 ÷ 50)% pure water and mixes it with air. Air is supplied through the ejector of the circulating pump. The water-air mixture (5 ÷ 6) enters the saturator at a pressure of atm. Here the air dissolves. The resulting mixture is transferred from the lower part to the entrance to the flotation chamber. When the pressure drops, the dissolved air separates from the water in the form of micro-bubbles. In this case, the microbubbles absorb the contaminants into the particles and lift them to the surface of the flotation zone.

The final stage of wastewater treatment

The treated water enters the intake chamber. Here, he joins his stream at the next destination. Collection and disposal of toxic chemicals at the end of the process is carried out according to the accepted methodology (according to the standards) ( Appendix № 4, p.9).

the process of separation of harmful substances in water takes place. The water leaving the separator is transferred to a flotation plant to repel harmful substances. Here, appropriate chemicals are injected into the system to capture these harmful substances. As a result, harmful substances - wastes "decompose" and combine around the electrolytes, rise (accumulate) on the water and from there are collected in special chambers.( Appendix № 4, p.9).

From here these substances are transferred to the compression device by a special pump. In the compaction apparatus, the waste is compressed and brought to the state of sludge. When a lot of cuttings are collected in these chambers, they are taken from there and sent to the relevant enterprises for disposal (under the Agreement). FIn the lottery, the first tank with a capacity of 60 m3 of chemically treated water is discharged. Here the water is stabilized and the chlorination process begins. The water is purified again through a special filter in the tank and transferred to the second tank with a capacity of 60 m3, as shown in the diagram. (Appendix № 4, p.5)

These tanks with a capacity of 60 m3 are connected to each other by a pipe with a filter inside. Water from the last tank is pumped to the filters. Four such filters have been installed in the treatment plant system. Two of these filters are 60 m3(Appendix № 4, p.10).

Depending on the volume of water received, these filters are connected to the system. If necessary, all of these filters can be activated within 24 hours. They merged into two groups. In each group, the water is first filtered through charcoal. In this case, the bad odor in the water is eliminated. In the second stage, the water is passed through four-stage (different fraction-size) sand filters. Substances and chlorine released after chlorination are removed from the water passing through these filters. Samples are taken from the filtered water for laboratory analysis.

Analizlərin nəticəsi müvafiq qəbul olunmuş standartlara (Appendix № 4, p.11),If appropriate, decontaminated water is discharged into the sewer line.

Purified water is analyzed each time in accordance with existing accepted standards, taking into account the harmful substances present in the water.

(Appendix № 4, p.11). Purified water with positive analysis is either reused for technical purposes or discharged into the sewer.

скачать dle 12.1